To disrupt the traditional monitoring and controls space by reducing complexity, increasing affordability, while providing an unparalleled user experience.

With roots in the consumer electronics space, our team has spent years developing user-centric mobile and cloud experiences. Having had the opportunity to work with amazing partners like Amazon, Apple, Google, and Samsung – we approach the commercial industrial application space with a viewpoint that is approachable, engaging, and easy to use.

The electronics industry has been crippled by supply chain disruptions. To prepare for the future, we redesigned our entire portfolio with simplicity, reduced component count, and part redundancy in mind. For the critical wireless and computing components, we doubled down, risk purchasing tens of thousands units worth of supply. We continue this philiosophy for each of our customers, adapting our hardware to their needs, while maintaining flexibility and reliability of supply.

Clever mounting solutions,

simplifying physical

product installation

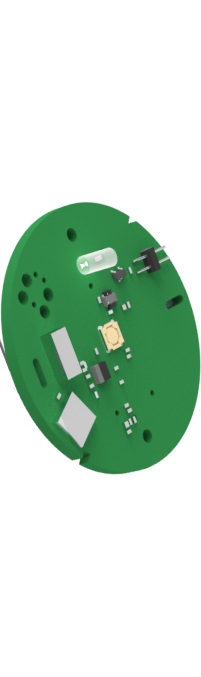

Powerful but simplified electronics,

capable of withstanding supply chain

shortages with the flexibility to adapt

to our customers unique needs

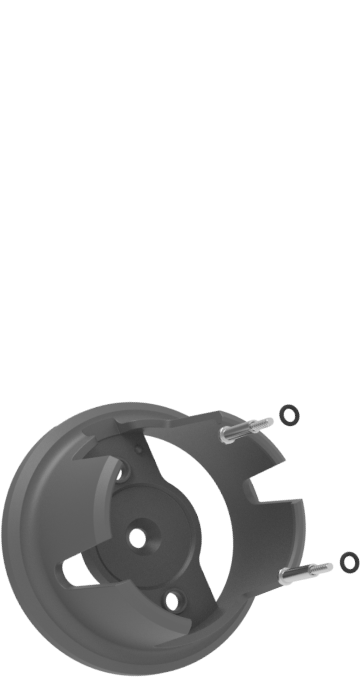

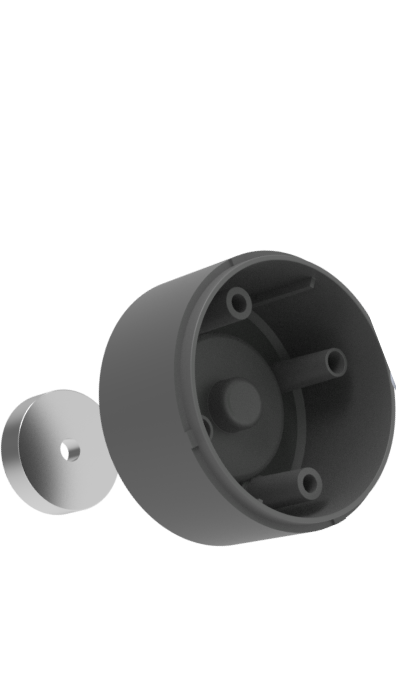

IP66 rated rugged

construction

Rugged and outdoor rated

industrial grade polycarbonate

housings

Based in the greater Boston area, the team at Preddio Technologies™ combines decades of experience in industrial and commercial IoT applications. After launching a widely successful sensor, cloud platform, and mobile application while working in partnership with A.W. Chesterton Company, the team realized the opportunity for similar IoT solutions across the industrial and commercial markets.

To capitalize on the overwhelming potential for IoT, Preddio incorporated in early 2020 to deliver its unique solutions to select customers. Preddio’s mission is to provide a platform of IoT smart solutions, exceeding our customers’ needs, creating a simple easy to use innovative monitoring system to operate their businesses in an efficient and cost savings manner.

Based in the greater Boston area, the team at Preddio Technologies™ combines decades of experience in industrial and commercial IoT applications. After launching a widely successful sensor, cloud platform, and mobile application while working in partnership with A.W. Chesterton Company, the team realized the opportunity for similar IoT solutions across the industrial and commercial markets.

Founded by entrepreneurs and talented innovators, our amazing employees are some of the most advanced in their field. Preddio believes it is important to provide flexibility and exciting rewards to its people.

We value family, friendships, and the enjoyment of “one team” to deliver results to our customers. We work hard, we play hard, and accomplish great things together.

There are many variations of passages of Lorem Ipsum available, but the majority have suffered alteration in some form, by injected humour, or randomised words which don’t look even slightly believable.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |